Best Practices to Prepare for Digital Transformation

Key Takeaways

- Top-performing manufacturing organizations will embrace digital transformation and Industry 4.0 opportunities as a way to optimize business processes.

- When it comes to Industry 4.0 opportunities, begin with alignment to overall business strategy.

- ERP, CRM, automation and data analytics are all crucial components of an Industry 4.0 strategy.

Embracing Emerging Technology from the Finance Office to the Factory Floor

Supply chain disruptions, labor shortages, and the state of the global economy have drastically impacted manufacturing operations and forced many entities into rapidly acquiring or scaling their technology capabilities.

The demand to increase efficiency in a highly competitive landscape through technology-driven change is at the heart of Industry 4.0 and its direct impact on the manufacturing industry.

- How can you use technology-driven change in your manufacturing organization? Download our digital transformation guide to create a plan today.

What is Industry 4.0?

Industry 4.0 refers to the Fourth Industrial Revolution, which focuses specifically on the digital transformation of organizations and the rapid implementation of technology and automation.

With a merging of artificial intelligence, robotics, IoT, IIoT, and other innovative technology and data-driven components that increase efficiency, Industry 4.0 has embedded itself into manufacturing.

In fact, McKinsey found that in operationally intensive industries, like manufacturing, there is 1.3 times more automation potential than in other industries. This equates to almost 60% of work that could be automated with current Industry 4.0 technologies.

Putting an Industry 4.0 Strategy into Place

When it comes to digital transformation and embracing Industry 4.0 opportunities, always begin with alignment to overall business strategy.

Effective change puts people and processes first. Streamlined processes help your employees be more productive, allowing for better customer service and more efficient operations overall.

Your workforce is key to helping you determine the areas within your operations that could benefit from optimizing technology. Look for opportunities to identify how processes really work and outline inefficiencies that you can immediately improve.

Leadership buy-in is also crucial to a digital transformation strategy. Only one-third of manufacturer respondents to the Oxford Economics survey said they made changes at the leadership level to align with a digital strategy. Executives who understand the value of change will help build a manufacturer of the future.

Many manufacturers that are implementing an Industry 4.0 strategy are still in the early stages or have stalled due to the difficulty of scaling across their entire network. That means there’s still a lot of opportunity to take advantage of.

What it doesn’t mean is abandoning everything you already do best. Incorporating Industry 4.0 ideas should enhance your operations and help you identify how to operate better.

Industry 4.0 Technology Tools to Consider

Specific examples of technology tools that can get you started in transforming your business into an Industry 4.0 organization include:

- Enterprise resource planning (ERP)

- Customer relationship management (CRM)

- Automation

- Data analytics and warehousing

This list is far from exhaustive, and adoption of new platforms and processes in manufacturing is as varied as the tools available.

The tools available aren’t necessarily all internally focused, either. For example, technology can give you better visibility across your supply chain, which can strengthen your relationships with partners and make those tough conversations about order status much easier.

This is even more important when your supply chain is upended. According to a survey from the Manufacturing Leadership Council, this problem is not likely to go away anytime soon and will likely last well into 2023 and beyond.

Technology can also level the playing field for smaller manufacturers trying to compete with the giants. It helps support an agile supply chain, while fostering innovation throughout an organization.

- Engaging an experienced manufacturing consultant can help you assess your best return on investment and build your roadmap to the future.

Enterprise Resource Planning for Manufacturers

Manufacturers often piece together multiple applications to run their operations. This infrastructure approach results in a lack of integration and limited visibility into essential business information. This results in manual tasks, bottlenecks and increased risk for error.

Prioritizing the expansion of digital resources and scaling current technology capabilities is necessary when it comes to changing market conditions and optimizing business models.

This begins with the establishment of a business management system designed specifically for your company’s needs. ERP systems are the backbone of Industry 4.0, with the power to orchestrate digital processes and provide real-time information to drive overarching strategy. The result is the necessary data needed to fuel the success of a product throughout its lifecycle.

To start, review your current business management system and ask: does this give me access to accurate information to drive decision making?

If not, the first step is updating the technology you use. A streamlined, cloud-based ERP can integrate inventory, supply chain, e-commerce, finance and more, increasing visibility and enabling you to react to customer and business needs in real-time.

Once your business systems are in place, look to other ways to optimize business processes.

Customer Relationship Management for Manufacturers

Your digital transformation should keep a focus on your customers and offer them a better experience. If you make it easier for your customers to do business with you, odds are they’ll come back more often.

A Customer Relationship Management system (CRM) allows you to get better data on your customers and track their journey. See how you can better serve them at every step of the buying process.

Leveraging the knowledge gained from a data-driven CRM system, manufacturers can begin tailoring their interactions with customers to be more personalized and specific. They can anticipate customer needs based off previous purchase orders or browsing history.

Pulling useful data from the CRM enables both sales reps and operations managers to see where each customer falls in the sales process at any given time, from a single location. Successful implementation of CRM systems can increase productivity and customer service.

Automation for Manufacturers

A critical element in digital transformation is building a more efficient operation overall, from the factory floor to the human resources office.

Business Process Automation (BPA) can help streamline processes such as hiring new employees, reconciling databases, fulfilling warehouse returns, tracking equipment details and flagging routine maintenance or replacements. Automations can essentially function as a digital project manager that seamlessly coordinates an entire process.

Robotic Process Automation (RPA), on the other hand, can totally transform manual, tedious and repetitious processes into hands-off, bot-controlled tasks that allow employees to spend more time on higher level work. From purchase order processing and order fulfillment to marketing and finance, RPA is a big component to many manufacturers’ Industry 4.0 strategies.

Data Warehousing and Analytics in Manufacturing

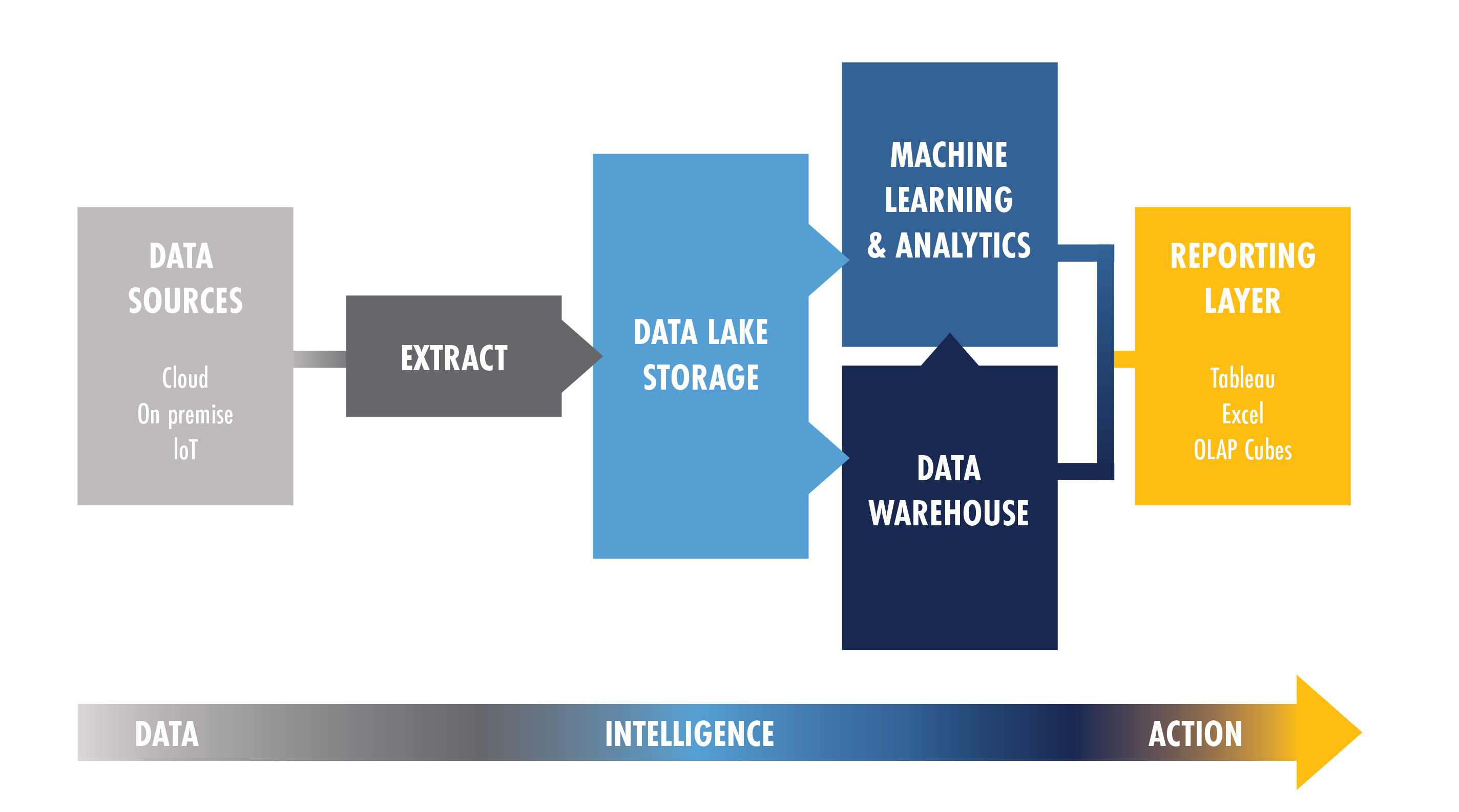

With a sound data strategy that takes into account all of your data (data sources, ETL processes, data storage, learning and analytics, and data visualization), you can be sure that your data is instant, accessible, and reliable.

Manufacturers are incorporating artificial intelligence (AI) and the Internet of Things (IoT) into their warehouses and workflow. IoT sensors provide valuable information about nearly every process, including inventory, supply chain, production line, and transportation.

Your operational and financial data can be combined with data from your IoT products to improve processes, make forecasts and reduce inefficiencies. Data analytics opens the possibilities for forecasting, warehouse management and supply chain improvements.

Next Steps Toward Industry 4.0

Today’s manufacturing environment requires a digital focus. Here’s how to get started:

- Assess your current technology climate. What tools do you already have that can serve you even better? For example, if you already use an ERP, does it have additional modules that would make sense to implement in your organization?

- Talk to your team. Your employees know where inefficiencies already exist or areas that create excessive mental tolls during the workday. Look for tools that lead to efficiency and increased productivity, coupled with ease of use.

- Engage with your supply chain partners. In today’s ever-changing supply chain environment, talking to your partners can help you identify gaps in processes. Use this to help guide your assessment.

- Don’t get discouraged if you can’t do it all at once. Digital transformation is not a destination, it’s a journey. The first step is to start; the second step is to continue. Identify the necessary action for quick wins that can get you started on the path to success.

Digital transformation and Industry 4.0 strategies are about so much more than new technology. A true digital transformation ties everything back to business-focused goals and growth across the organization.

Manufacturing

Rely on the trusted expertise of manufacturing advisors to help you build and execute your strategic vision.