Key Takeaways

- Manufacturers must embrace advanced technologies for resilience. By adopting tools like AI, cloud-based analytics, and IoT, manufacturers can transition from reactive to proactive strategies.

- Technology can empower manufacturers with real-time insights into supply chain, production processes, and customer behavior.

- Successful digital transformation and optimization requires a well-rounded approach, not just adoption of the latest technology.

Manufacturers have continued to face a fluctuating marketplace fraught with challenges. Fortunately, resilience in the industry has led to optimistic outlooks. More than 80% of manufacturers expect to increase their revenue in 2024.

Through the use of advanced tools and capabilities powered by artificial intelligence (AI) and Industry 4.0 technologies, manufacturers can reduce vulnerability, improve efficiency, and utilize real-time data to drive decision making.

Here are major tech trends for manufacturers to consider in 2024 — and ways manufacturers can design their digital future in a way that will best position them to harness everything innovation has to offer.

1. Artificial Intelligence

Artificial intelligence (AI) is a mainstream reality for the manufacturing industry. The Manufacturing Leadership Council found that 96% of manufacturers plan to increase AI operational investments by 2030.

Today’s AI functionality case be used across a wide range of applications, including:

- Production line scheduling

- PDF scanning for administrative task automation

- Predictive maintenance on equipment

- Quality control

- Supply chain forecasting and demand planning

- Personalized manufacturing

And with new generative AI (genAI) capabilities, it will be possible for manufacturers to have conversational interactions with machines, enabling natural language troubleshooting.

AI has numerous benefits, including cost reduction, enhanced decision-making, and improved productivity. You can read more about what the evolution of AI in manufacturing looks like in our latest article.

Despite the benefits, however, almost half of manufacturers still categorize their AI usage as experimental. This signals a significant growth area for manufacturers to tie AI into their existing digital modernization strategy.

2. Cloud-Based Analytics & Optimized Systems

The convergence of AI, machine learning, cloud-based analytics, and real-time data from embedded IoT sensors and connected devices helps create better visibility into the entire supply chain — including everything from the production line to materials, suppliers, and transport, as well as customer behavior.

More than seven in 10 manufacturers are planning to invest in Industry 4.0 technologies. After all, more connectivity and predictive analytics make it possible to plan potential scenarios in advance. The result is increased proactivity, coupled with optimized systems and collaborative tool options.

The wrong strategy and infrastructure can lead to poor performance and end-user frustration. For one manufacturer, not only did their production ERP perform poorly, but analytics reporting took a significant programming effort with end-users unable to generate new reports without support from a developer. By rethinking their data infrastructure and strategy and migrating to a cloud data warehouse, they eliminated performance issues and empowered their employees to make faster data-driven decisions.

3. IoT: Smart Factories and Warehouses

The steady stream of real-time data IoT sensors provide has made it possible for both warehouses and factories to streamline processes. This has reduced or eliminated wasted time and effort all while enhancing worker safety.

Applying insights from machine learning to IoT data makes it possible to continuously adapt and improve processes while also empowering more informed strategic choices for the future. For example, AI-derived insights can help you make better decisions about stocking and organizing warehouses to improve speed and efficiency.

One in five manufacturers is experimenting with smart factory solutions. From predictive maintenance to data analysis, digitally mature manufacturers often demonstrate greater resilience in the face of challenge and change.

4. Supply Chain Management and Visibility

On a big-picture level, an integrated approach that leverages cloud-based analytics and intelligence provided by IoT sensors helps you to visualize your entire supply chain, from beginning to end — so you can spot inefficiencies and identify areas for improvement.

One of the most important keys to a more robust and resilient supply chain is better collaboration and data-sharing between partners and suppliers — a capability that’s increasingly emphasized in the newest and best supply chain technology solutions. In fact, a McKinsey study found that 45% of businesses have limited supply chain visibility. This can lead to significant disruption and inefficiency for manufacturers.

Proactively mitigating supply chain risk and optimizing your technology partnerships can save you time and money in the long run. In fact, 79% of companies with a strong supply chain achieve significantly higher revenue growth.

For Cheerleading Company, agile, scalable technology that supported growth was not even an option. Dated systems led to significant limitations. By implementing a robust Salesforce solution across the organization – from lead through fulfillment – the company is now able to manage every aspect of its business in one place with repeatable workflows.

Read the case study.

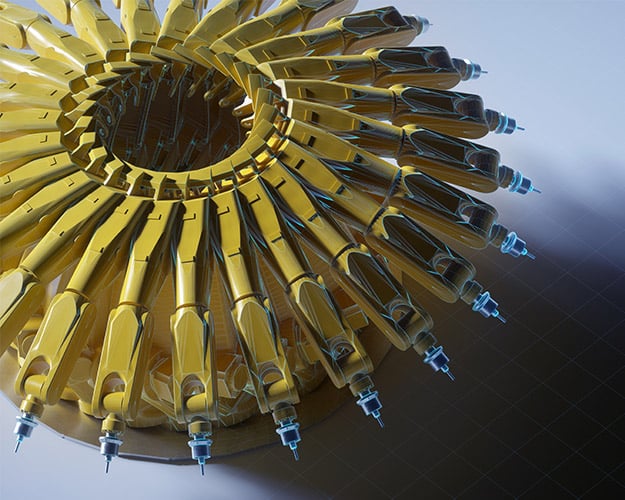

5. Robotics and Automation

Integrating robotics and automation into production processes will continue to improve efficiency, not only by helping to fill labor shortages but by freeing up team members to focus on more sophisticated tasks as repetitive functions are increasingly automated. Robotics can also improve workplace safety, taking over tasks with a higher risk level to help keep employees safe from injury. Overall, such improvements across the board help manufacturers retain talent in a challenging labor market.

It’s not just production processes that benefit from automation; automation can have a tremendous impact on security processes. The World Economic Forum reports the industry most targeted by cyberattacks is manufacturing. With the increasing connectedness across the supply chain and move to more advanced technology, maximizing cybersecurity capabilities is vital. By 2025, the lack of cybersecurity professionals will be responsible for more than 50% of significant cybersecurity incidents.

Read more about how to use automation to enhance security and efficiency.

The Five Keys to a Successful Digital Transformation

If a technology solution is trending, that doesn’t necessarily mean it’s right for you, and it certainly doesn’t mean you should adopt everything at once and expect a sustainable or meaningful transformation.

There are five crucial factors that are essential to a successful digital transformation, and each of these can make or break your efforts.

Successful digital transformation depends on the following:

-

Data

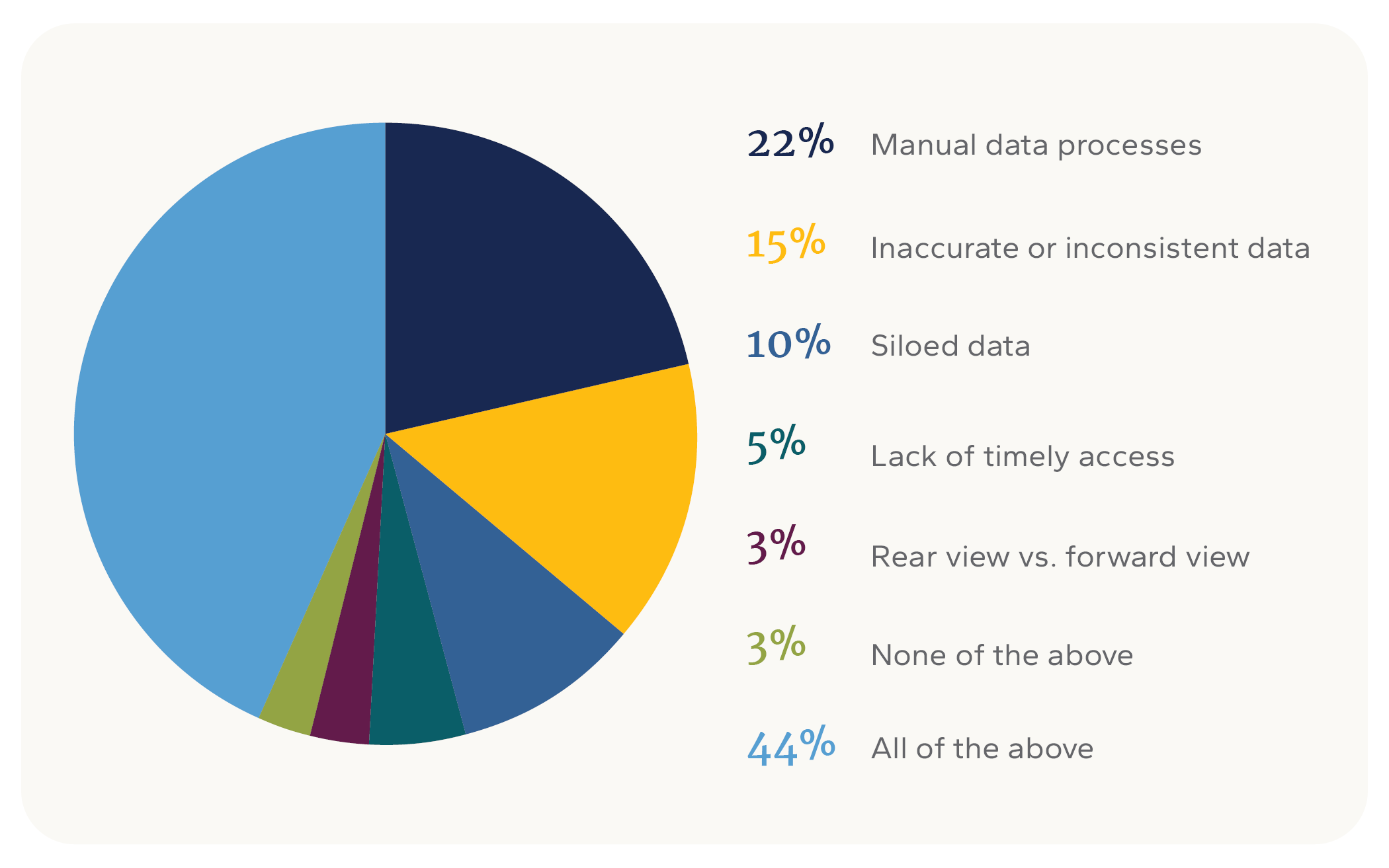

In our recent survey, business leaders identified the impact of poor data on their organizations.

Data is the most important asset to your business, and high-value technology initiatives rely heavily on quality, accessible data. The first step toward a digital future is preparing your data. A data assessment will help you create or review your data strategy. Creating a plan for governance, architecture, analytics, management, and technology will ensure you get the most value out of your data.

-

Careful Planning

You’ll achieve better success if you take the time to create a roadmap for your digital transformation ahead of time. Figure out what you want to achieve and create a unified, step-by-step plan that takes into account your people, processes, and technology. This includes listening to all the organization’s key stakeholders to determine their needs and how the right technology can solve problems and enable them to reach their goals.

-

Company-Wide Adoption

Digital transformations won’t succeed if team members don’t embrace it throughout the entire organization. For this reason, it’s imperative to make sure all hands understand the goals of the process and the ways the transformation will benefit them by making their jobs easier and processes more efficient by reducing tedious and repetitive tasks.

-

The Right Fit

Choosing the right technology solutions for your needs is a process you shouldn’t rush — but the sooner you get started, the sooner you can identify the right set of tools for your needs, and the sooner you can leave behind the limitations of outdated legacy software. Most importantly is that your technology is able to be connected across your organization. View our panel discussion on creating a high-value technology strategy to learn more about one manufacturer’s technology journey.

-

The Right Partner

To navigate this process successfully, it helps to have an experienced consulting partner who knows the territory and can help you avoid the common pitfalls as you move from planning to implementation and ongoing maintenance.

For example, Eide Bailly had the opportunity to work with Bio Huma Netics, Inc. to overcome challenges related to their disparate, multi-system technology infrastructure. Bio Huma Netics manufactures and distributes fertilizers and humic substances. Their operations are complex, and they needed a team that could understand that complexity and identify a fitting solution. The Eide Bailly team created a custom solution with NetSuite for Manufacturing and RF-SMART, and the outcomes have been incredible.

Trends are ever changing, but strategic planning with business goals in mind can help any manufacturer become more digitally optimized. We can help you make the most of new opportunities and challenges by identifying the right strategy and technology for your manufacturing operation.

The Use of AI in Manufacturing

Manufacturing, Distribution, and Logistics

Rely on the trusted expertise of manufacturing advisors to help you build and execute your strategic vision.